The Metal Bending Machine – Transforming Industries

The metal bending machine, a versatile and powerful tool, has revolutionized the manufacturing and construction industries. With its ability to precisely shape and form metal sheets and pipes, this essential piece of equipment has transformed the way metal products are fabricated and has significantly impacted various sectors such as automotive, aerospace, architectural design, and many others.

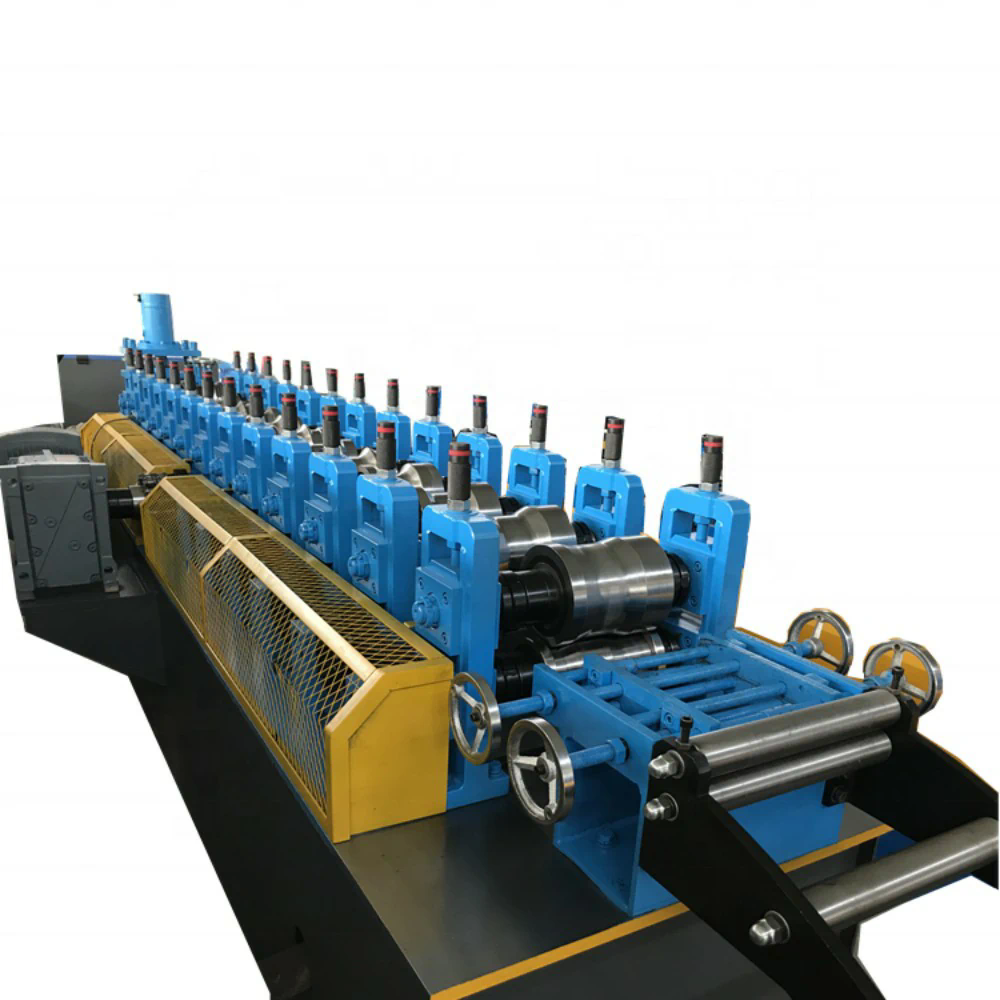

Metal bending machines come in various types, including press brakes, tube benders, and roll benders, each designed for specific applications. These machines utilize hydraulic or mechanical force to deform metal materials, offering a range of capabilities from simple bends to complex shapes. The advent of computer numerical control (CNC) technology has further enhanced the precision and efficiency of metal bending operations, allowing for seamless integration into modern manufacturing processes.

The Evolution of Metal Bending Machines

The history of metal bending machines dates back to the industrial revolution, where manual tools such as hammers and anvils were used to bend and shape metal by hand. As technology advanced, mechanical and hydraulic-powered bending machines emerged, enabling faster and more precise metal forming. Today, CNC metal bending machines have become the standard, offering unprecedented accuracy and repeatability in production environments.

Applications in the Automotive Industry

In the automotive industry, metal bending machines play a crucial role in the production of vehicle components such as chassis frames, exhaust systems, and body panels. These machines enable the fabrication of complex and intricate parts, ensuring the structural integrity and aesthetic appeal of automobiles. With the ability to work with various metals including steel, aluminum, and titanium, metal bending machines have contributed to the lightweighting trend in automotive design, improving fuel efficiency and performance.

Impact on Aerospace Manufacturing

Aerospace manufacturers rely heavily on metal bending machines to produce aircraft components that meet stringent safety and performance standards. From structural elements to engine parts, these machines enable the precise bending of metal alloys essential for building reliable and efficient aircraft. The ability to work with exotic materials and create intricate geometries has made metal bending machines indispensable in the aerospace industry, driving innovation and pushing the boundaries of flight technology.

Architectural and Structural Design

In architectural and structural design, metal bending machines have expanded the possibilities for creating unique and visually striking building elements. Curved metal beams, ornate railings, and custom facade panels are just a few examples of the applications made possible by advanced bending technology. Architects and designers can now realize their creative visions with greater ease, incorporating curved metal elements into modern constructions for both aesthetic appeal and functional benefits.

Advancements in Material Handling and Automation

Recent advancements in metal bending machines have focused on improving material handling and automation capabilities. Integration with robotic systems has streamlined the production process, reducing manual labor and increasing throughput. Furthermore, the development of adaptive bending technology has enabled real-time adjustments during the bending process, ensuring consistent quality even with variations in material properties.

Challenges and Opportunities

While metal bending machines have undoubtedly brought about numerous benefits, they also present challenges that need to be addressed. The complexity of bending certain materials, such as high-strength alloys and exotic metals, requires ongoing research and development to enhance machine capabilities. Additionally, the demand for sustainable practices in manufacturing has led to the exploration of eco-friendly lubricants and energy-efficient machine designs, presenting new opportunities for innovation in the industry.

Future Trends and Innovations

Looking ahead, the future of metal bending machines is poised for continued innovation and https://cnmtrollformingmachinery.com/vi/sea_containers_equipment/ roofing sheet production machine evolution. Advancements in artificial intelligence and machine learning are expected to further optimize bending processes, leading to improved efficiency and reduced waste. 3D metal printing combined with bending technology may open up new frontiers in customized, on-demand manufacturing, while the exploration of lightweight composite materials will drive the development of specialized bending equipment for emerging industry needs.

The metal bending machine has undeniably transformed industries across the board, from automotive and aerospace manufacturing to architectural design and beyond. Its ability to shape and form metal with precision and efficiency has elevated the capabilities of modern engineering and fabrication. As technology continues to advance, the potential for further innovation in metal bending machines is limitless, promising a future where complex metal components can be created with unprecedented speed and accuracy, driving progress and shaping the world we live in.

https://ortumeta.com/