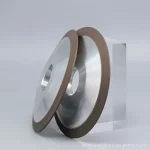

What are the characteristics of grinding wheels and how to choose them A grinding wheel is a precision tool used in various industries for grinding, cutting, and polishing purposes. It consists of abrasive particles bonded together by a matrix material, forming a solid and durable wheel. The characteristics of grinding wheels play a crucial role […]